Most folks don’t realize it, but “good enough” IT is usually a ticking time bomb—and the fuse is already lit.

You don’t notice it when things are mostly working. Printers connect (most days). Scanners read (after two tries). Files save (eventually). So, no one complains too loudly.

But here’s what happens: that daily friction starts to add up. One delay becomes two. A machine loses connection. A scanner hangs. Someone has to reboot a terminal. Then the line stalls.

And just like that, you’ve lost thousands—and you can’t even point to a fire.

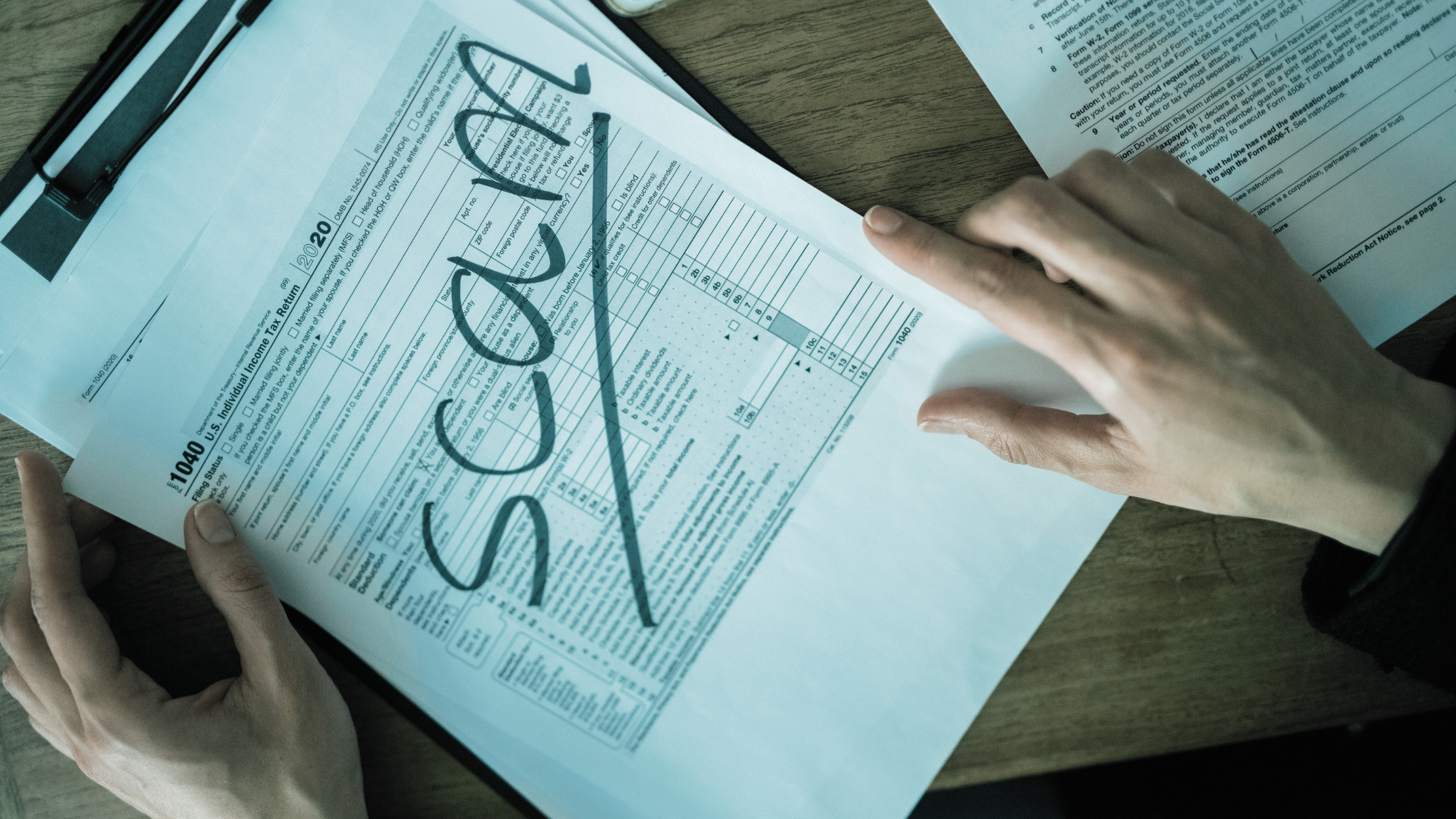

Death by a Thousand Glitches

A plant manager told me his crew was manually logging downtime because the tracking system kept crashing. They figured it was just a glitch. Turns out, the workstation had been throttling itself to avoid overheating. Fan was full of dust. IT never caught it.

Another shop had label printers go out twice a week. Not a big deal—until a batch got mislabeled and 900 parts had to be reworked.

A stamping facility in Ohio dealt with a wireless dead zone in one corner of the warehouse. No one thought much of it—until a pallet of high-dollar inventory was scanned into the wrong location three times. Took a full day to sort out.

These aren’t dramatic breakdowns. They’re slow leaks. And over time, they bleed money, morale, and trust.

What “Good Enough” Really Costs

- Lost production time from flaky logins, failed scans, and slow load times

- Overtime costs because a system delay caused a bottleneck

- Scrap and rework from mislabeled or misrouted parts

- Fire drills that pull supervisors and IT off their actual jobs

- Frustration that builds on the floor, quietly killing morale

- Trust erosion between departments—IT, Ops, QA—because no one knows where the real problem lies

All of it drains your bottom line—without ever triggering a red light on the dashboard.

Why It Happens

A lot of MSPs and internal IT teams focus on “keeping the lights on.” They patch what breaks. They respond when screamed at. But they don’t think like operations people. They don’t walk the floor. They don’t watch how systems interact.

In one facility, the IT team proudly kept every Windows patch up to date—but didn’t realize that every update rebooted a shared PC during second shift. Caused months of mid-job crashes. No one tied it back to patching until we did an audit.

They meant well. But they weren’t thinking like plant people.

How to Plug the Leaks

- Audit everything. Look for small glitches—printer queues, scanner retries, log errors—and track their impact.

- Walk the floor. Sit with operators. Ask what bugs them. You’ll learn more in 20 minutes than in a month of tickets.

- Log minor IT incidents. Patterns will emerge that reveal bigger issues.

- Tag true root causes. Don’t settle for “user error” or “connectivity issue”—dig until you know why.

- Choose an MSP who understands production urgency. Not just one who closes tickets.

- Invest in proactive tools. Monitoring, remote management, and alerting tools that catch issues before they impact output.

Final Thought

“Good enough” might keep the lights on—but it won’t keep the line moving.

You’ve worked too hard to let silent tech issues chip away at your margins. The little things—laggy logins, forgotten patches, dusty fans—matter more than folks admit.

It’s time to stop settling—and start fixing the little things before they become big ones. Because downtime doesn’t always start with a bang. Sometimes it starts with a blinking cursor and a crew waiting on a label to print.